On this page... (hide)

- 1. Introduction

- 2. Design

- 2.1 Hand Benchmarking

- 2.2 Design Overview

- 2.3 Compliant Joints

- 2.4 Waterproofing Design

- 3. Sensors

- 4. Simulation

- 5. Experiments

- 6. Links and Related Projects

1. Introduction

1.1 Underwater Robotics Explorer

Lying between Africa and Asia, the coastal zone of the Red Sea is an ecologically unique marine ecosystem that houses one of the most extensive, diverse, and colorful coral reefs in the world. The coral reef, with its many endemic species of marine invertebrates and fish, provides a vital research platform for studying how humans impact marine ecosystems.

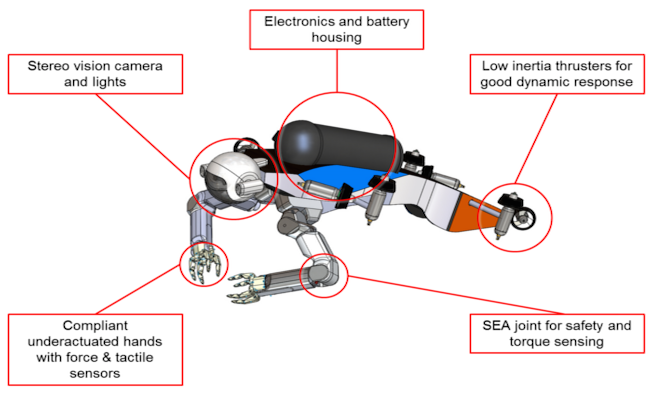

To help scientists safely explore the Red Sea’s fragile and previously inaccessible underwater environment, a semi-autonomous underwater robotic explorer is proposed and being designed by collaboration between KAUST, Stanford and Meka Robotics (The Red Sea Exploratorium). The new vehicle will visually explore and image the sea, collect samples, perform manipulation tasks, and conduct various physical measurements in multiple marine ecosystems. The robot will combine two force-controlled lightweight arms that will be remotely operated using an intuitive two-handed haptic interface providing force-feedback guidance to the operator.

Past design of the underwater robot

1.2 Compliant Underactuated Hand for Underwater Mobile Manipulation

For this robotic explorer, we are designing an underactuated, flexible, tendon-driven hand that can perform reliably underwater through achieving a broad range of grasps necessary for oceanic exploration. Multiple design iterations have led us to a highly compact, waterproof palm which minimally contributes to detrimental end-effector inertia effects. We are also developing sensors necessary for the hand control and mobile manipulation, including tactile sensor, joint encoder and tendon force sensor.

2. Design

2.1 Hand Benchmarking

2.2 Design Overview

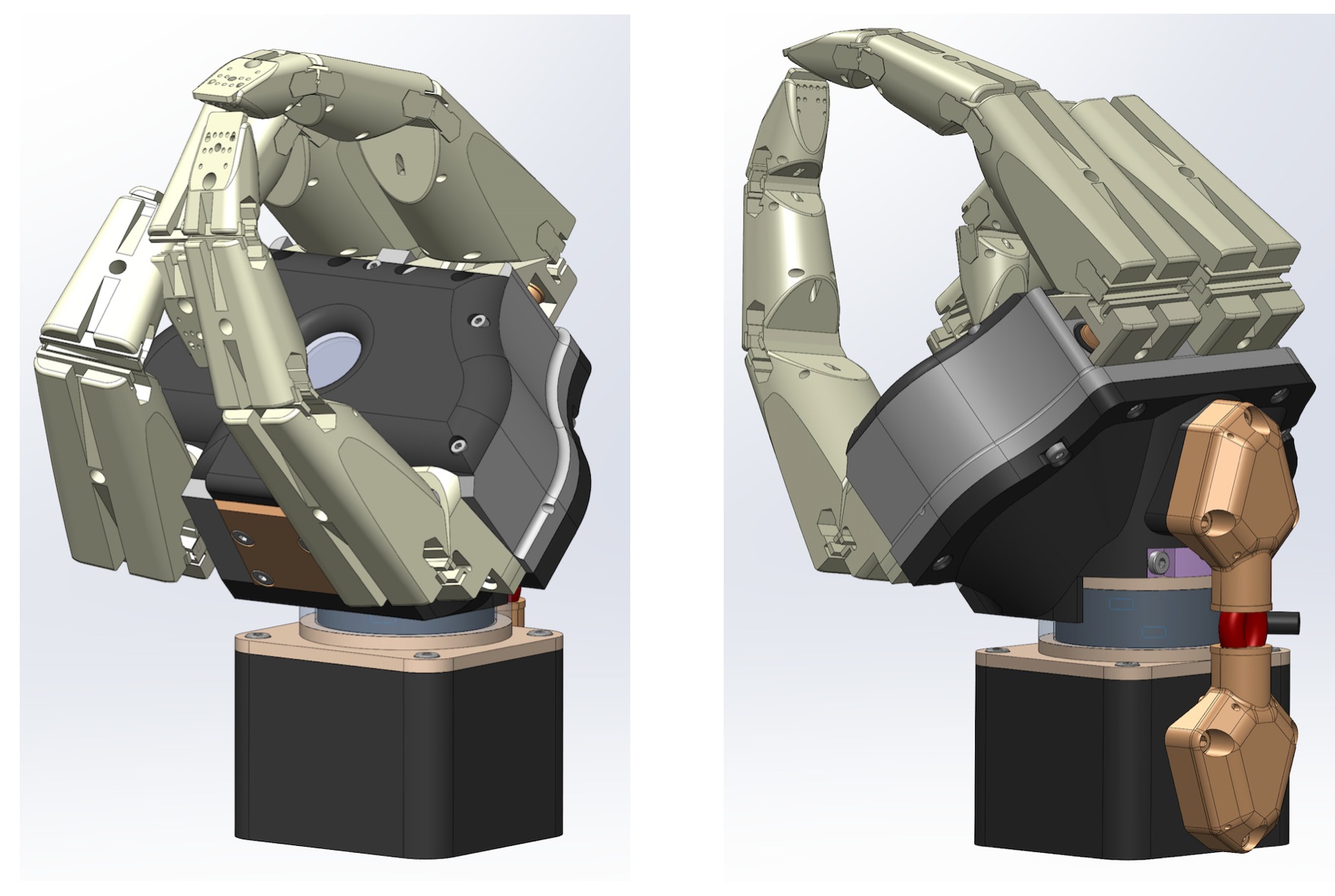

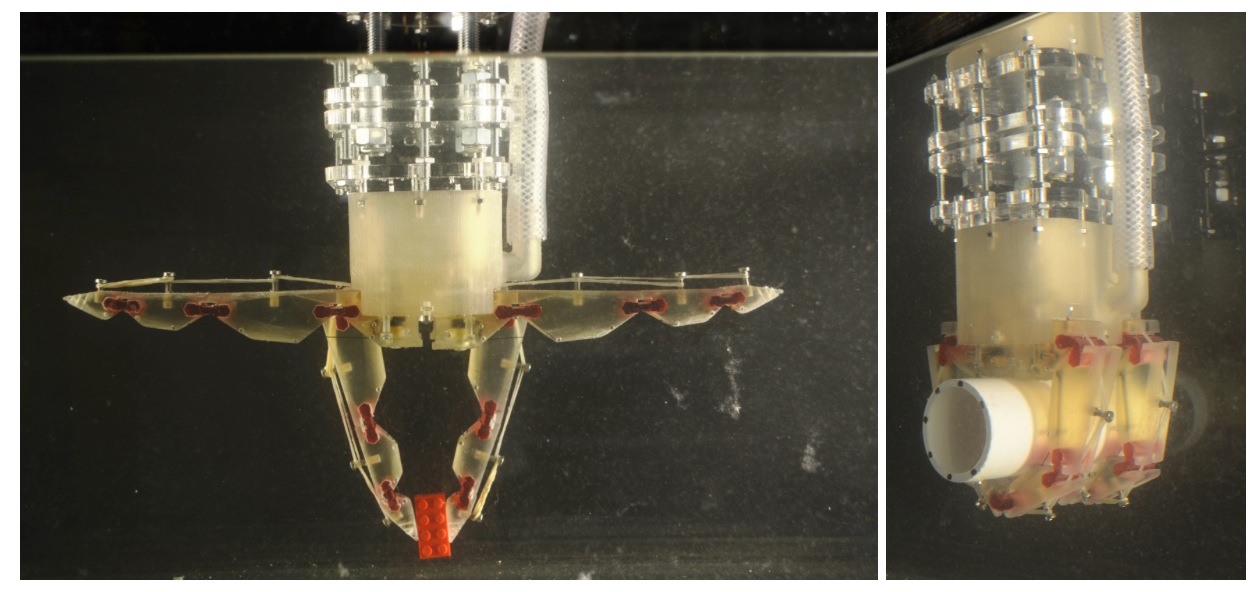

Current design of the underwater hand

2.3 Compliant Joints

- Development of UB Hand 3: Early Results

- Integrated Mechatronic Design for a New Generation of Robotic Hands

2.4 Waterproofing Design

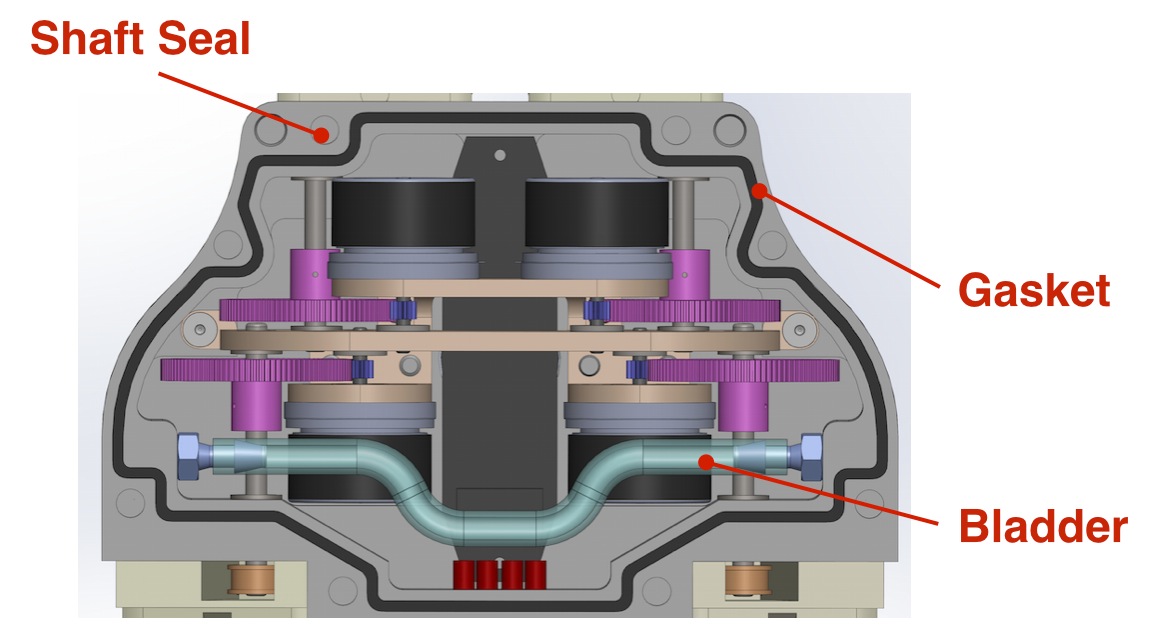

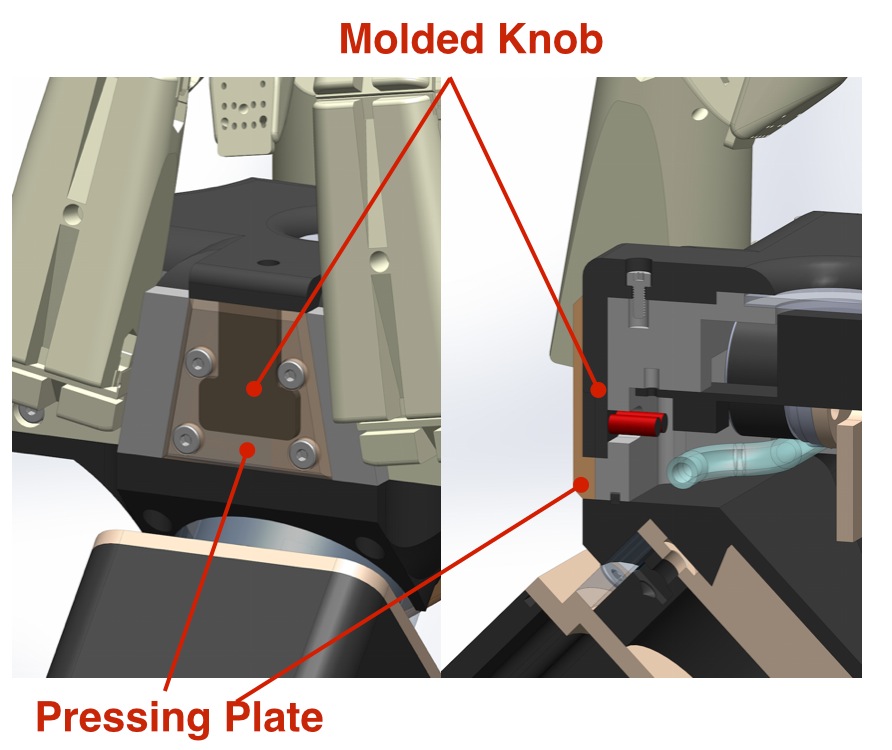

Waterproofing methods including self-sealed screw, laser-cut gasket, rotary shaft seal, o-ring, rubber coating are applied to make the hand waterproof. The entire palm has oil filled inside to lessen the burden of waterproofing parts. All motors are brushless for the oil filling method. A silicone bladder is designed to balance the pressures inside and outside the hand.

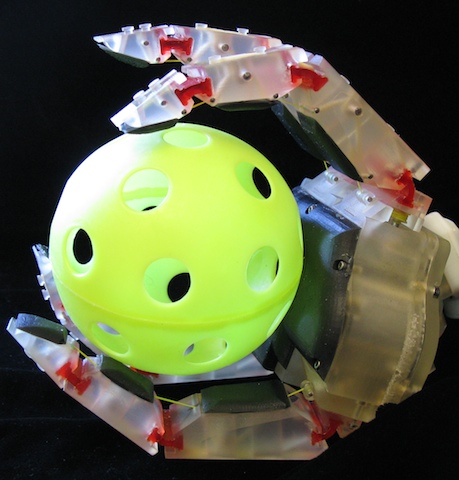

prototype without pads, showing palm camera

prototype with pads, grasping a sphere

3. Sensors

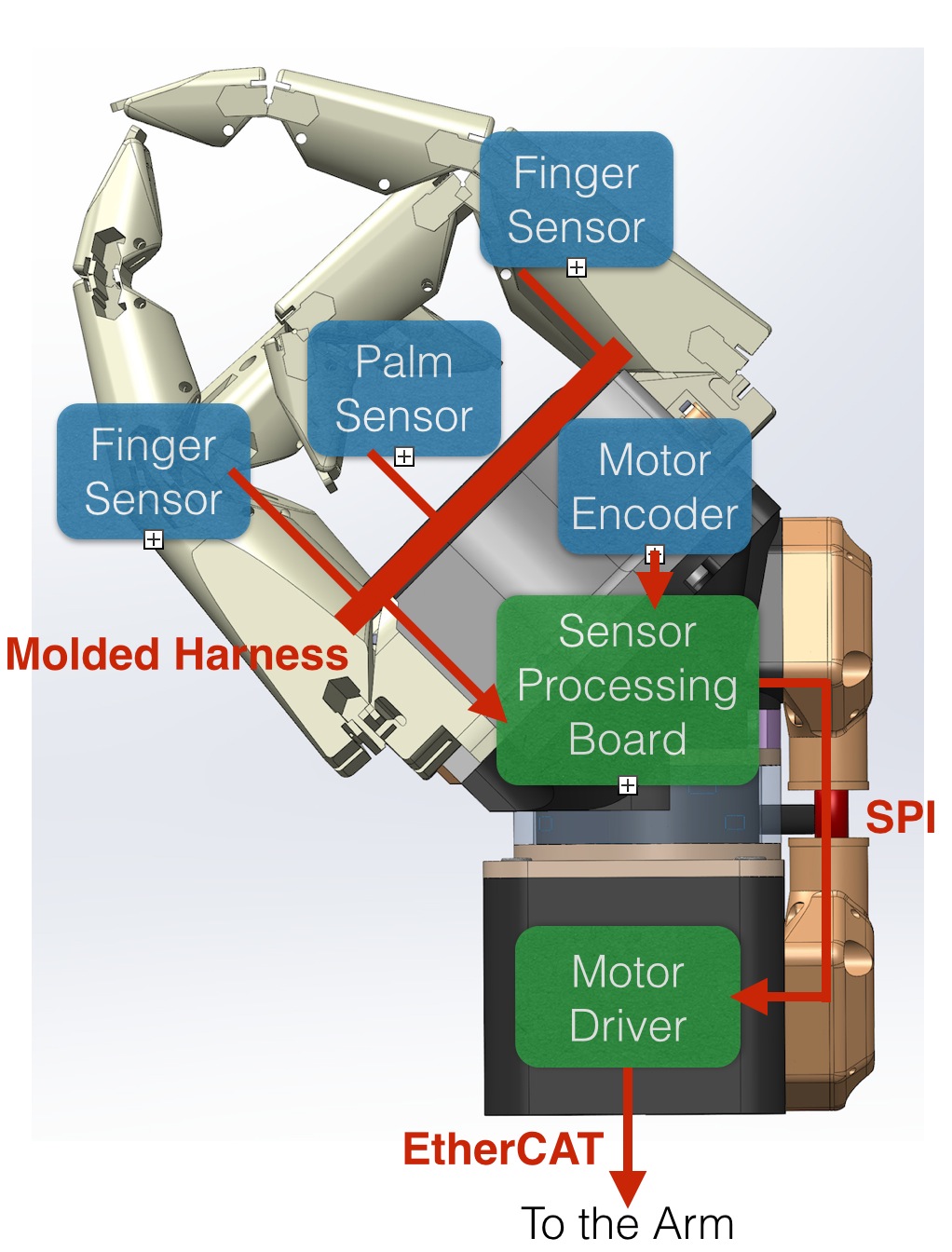

All the tactile sensors on the fingers and palm are molded to be waterproof. The finger sensors are designed as modular parts that can be detached from the central harness (palm sensors). All the sensors are processed by the signal processing board inside the palm into SPI signals. The sensors for our hand include tactile sensor, hall-effect joint angle sensor, tendon force sensor and torque sensor on the wrist.

Sensors and the wiring

Tactile Sensing

We are using an IR emitter/detector method developed in the following work:

- Lucas Samuel Lincoln, Morgan Quigley, Brandon Rohrer, Curt Salisbury, and Jason Wheeler, An Optical 3D Force Sensor for Biomedical Devices, 4th IEEE Intl. Conf. on Biomedical Robotics and Biomechatronics, 24 March 2012

It was also used in the Sandia Hand.

For more details on our fabrication development of these sensors in the Red Sea Hand: Tactile Sensing for the Red Sea Hand.

Compliant Joint Sensing

- L. Jentoft and R. Howe, Force sensing with compliant joints, 7th ACM/IEEE Intl. Conf. on Human-Robot Interaction, 5 March 2012, Boston.

- L. P. Jentoft and R. D. Howe. Determining object geometry with compliance and simple sensors. In 2011 IEEE/RSJ Int. Conf. Intelligent Robots and Systems (IROS 2011), pages 3468 –3473, sept. 2011.

FlexureSensing - new page started

Tendon and Force Sensing

- Differential tendon sensor -- Kaneko (1990)

- J.K. Salisbury: Kinematic and force analysis of articulated hands. In: Robot Hands and the Mechanics of Manipulation, ed. by M.T. Mason, J.K. Salisbury (MIT Press, Cambridge 1985) -- this describes the cantilever beam and strain gage sensor used to measure tendon tension in the Stanford/JPL hand. There is also some mention of it in US Patent 4921293 (online).

- An compact inline element with strain gages is used in RTR2 hand from SSSA Pisa in combination with a crimped cable stop.

- The Spring Hand from SSSA is a later hand that also uses strain gage tendon sensors and some interesting pulley differential elements and springs.

- MIT Design thesis by C. Anderson (1992) concerning the WAM arm prototype and its control.

4. Simulation

4.1 Kinematic Grasping Test

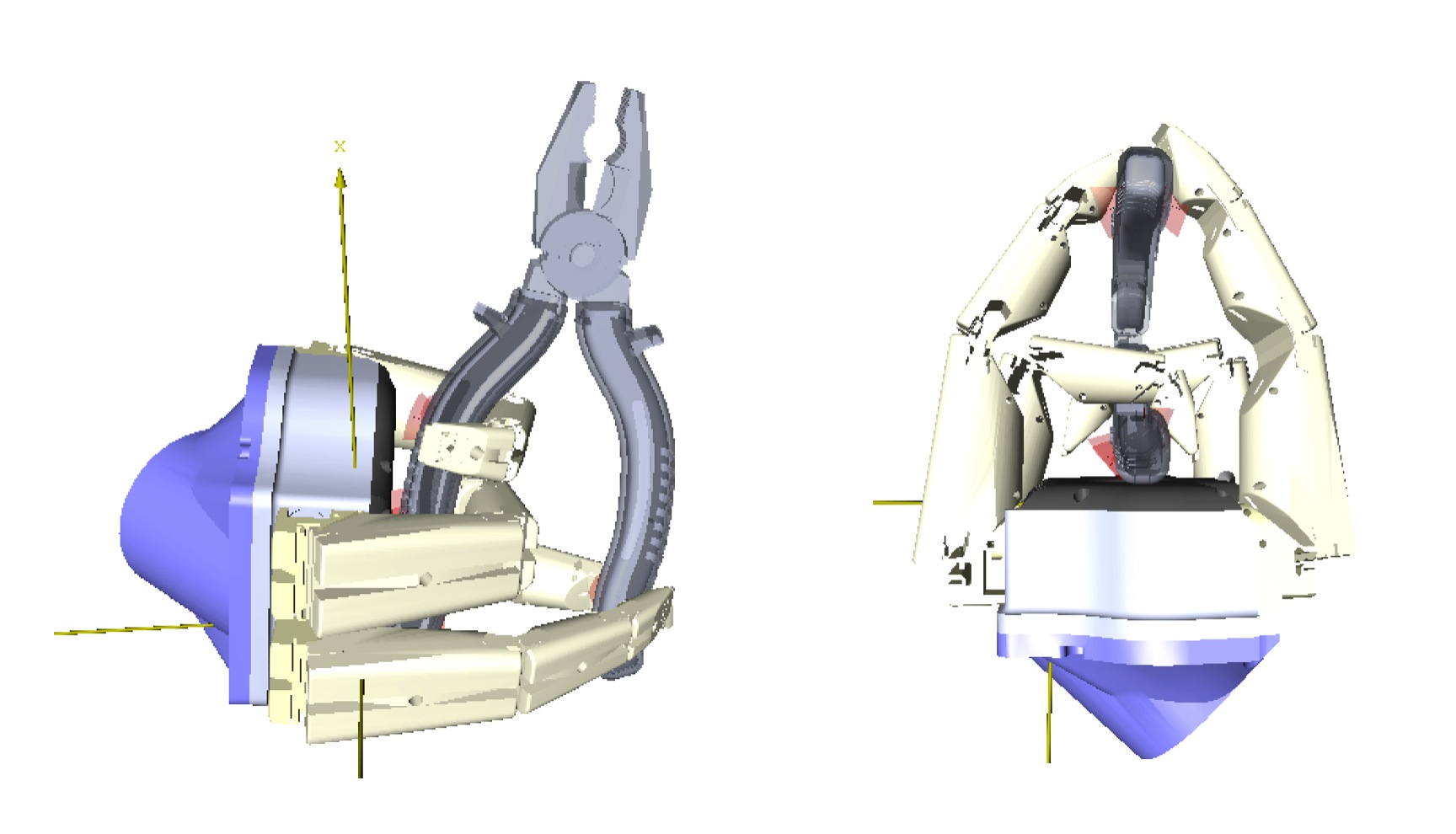

We use GraspIt, an open source simulator, to check the grasp performance of the hand, help iterating the design, and provide insights for grasping strategies.

GraspIt simulation of grasping a plier

4.2 Dynamic Simulation

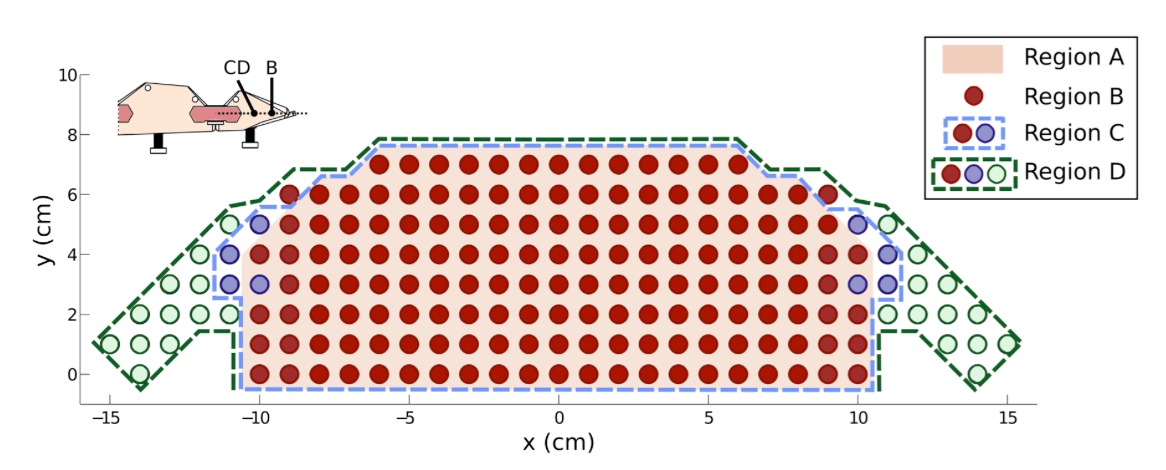

To evaluate grasping performance of the hand underwater more accurately, the dynamics of fluid and the hand need to be considered. We use the dynamic engine Moby with the python interface developed by D. M. Aukes which allows us to model all the relevant factors flexibly. In one of our simulations, we investigated the benefits of adding gentle suction at different locations on the fingers by including a simplified suction model into the simulator. Grasp regions with varying suction locations was generated using the simulator:

Grasp regions with varying suction locations

5. Experiments

Several underwater grasping tests were performed to verify the hand designs and the simulation results.

Underwater grasping tests