category: SummerBlogs

Joel's 2019 Summer Blog

Week 8 - 9

5-15 August: The TRI robot hand after some final tweaks got its first functioning prototype made without any of the sensors that will go on the final version. This model was simply to figure out tendon routing issues do simple force sensing and testing of the active suction palm. The palm uses particle jamming to allow the robot to be able to latch onto any potentially wet surfaces in the sink, while also help grasp objects that are very flat and not in a convenient orientation for the fingers to flip over and grab properly. Wilson had me make a couple of wiffletree bars out of steel to go on the hand which will help ensure equal forces are applied across all the fingers. We also got the hand set up on the UR5 to do move around some dishes and see how it performs with a curved, flat, wet, or dry surface.

Week 7

29-31 July:After helping get the robot set up for testing Amar showed me some of the basics on using a CNC since we needed new gecko adhesives for the gripper fingers. Also, fresh adhesives would give more unbias results during testing of wear and tear. Our next issue came from slight vibrations of the ur5 shifting the position in which the test surface was placed after gripping and moving. I designed a small support piece which our block will slide into and fix any movements caused by the vibrations in its position.

Week 5-6

15-26 July: With the ocean 1k project getting rescheduled, I was tasked with helping the Ford team (composed of Amar, Amy, and Capella) with doing wear and tear testing of their latest gecko gripper adhesive using the UR5 robot and Robotiq grippers available in the lab. The idea was to use the UR5 to do a thousand grasps on an aluminum block with a clean surface, which we could take pictures of before and after testing to check if any gripper residue is left behind after multiple cycles or if the grippers themselves became damaged after repetitive usage. A simple task that proved more difficult due to issues in communication between the gripper and our code. As a backup, we borrowed a gripper from a neighboring lab and that worked well to do initial testing along with fine-tuning of the code.

Week 4

10-12 July: The ocean 1k project got pushed back so we adjusted our timeline to get some additional rounds of testing both in water and on the precious ocean1 robot. As such, we are also moving on to the TRI project and doing more work on that hand since it is much more involved with regards to circuitry and sensing needs. Aside from those two projects, Mark is giving me a chance to learn to program the UR5 robot in the lab to help do basic testing for another team. This was a fun process because I could take some of the built-in commands and assemble my own program to have the robot move. The next challenge comes with getting the interface to also communicate with the gripper hand we will be attaching later on and excited to see how that will go.

8 July: the first prototype was good and we are keeping it around for more testing while we build up the second prototype. The urethane finally came in so all the molds for fingers and palms can be made and attach them to the new base that we printed over the weekend.

Week 3

1-3 July: We finally got the hand into the water for some simple rounds of testing. It worked great with simple shapes and we eventually moved it up to grasping a hand drill. It worked great and this was while the motor was using only around 3 volts of power. I'm very excited to begin working for the next iteration of the hand because my palm mold will go on that one and we can compare it to the current palm version.

Week 2

26-28 June: This week was kind of slow for the ocean 1k project in terms of things to design and assemble. However, everything is ready to test as we have now finished molding the palms that will potentially go on the hand. We used VytaFlex 40 for both palms(one was designed by Wilson and the other by myself) because at the moment we want to test structure performance and not materials(which is for later testing). As a side project during the downtime for Ocean 1k, Wilson got me started on a fruit picking gripper project which I'm excited about because there isn't a whole lot which people are attempting and gives me lots of room to explore ideas.

25 June: After talking with Wilson and Rachel we fine-tune my palm design into something that'll be easier to mold and have ready for testing. I'm excited to see how the palm will function once on the robot and make edits from any data we collect during testing. We ordered the supplies to create an underwater area to see how the hand will perform with interference in the water. Got to sit in a meeting with Wilson and Rachel to iron-out the timeline for the Ocean 1k project as well as who will spearhead certain tasks needed to get the current prototype ready for the next phase.

24 June: Today we will be doing testing on the hand with its ability to grasp differently shaped objects, while eventually testing it while in water to see if that has any impact(positive or negative). Over the weekend Wilson had me design a simple palm to help the hand better grasp objects. It was a fun task and sometime early this week we will mold it and mount it on the hand.

Week 1

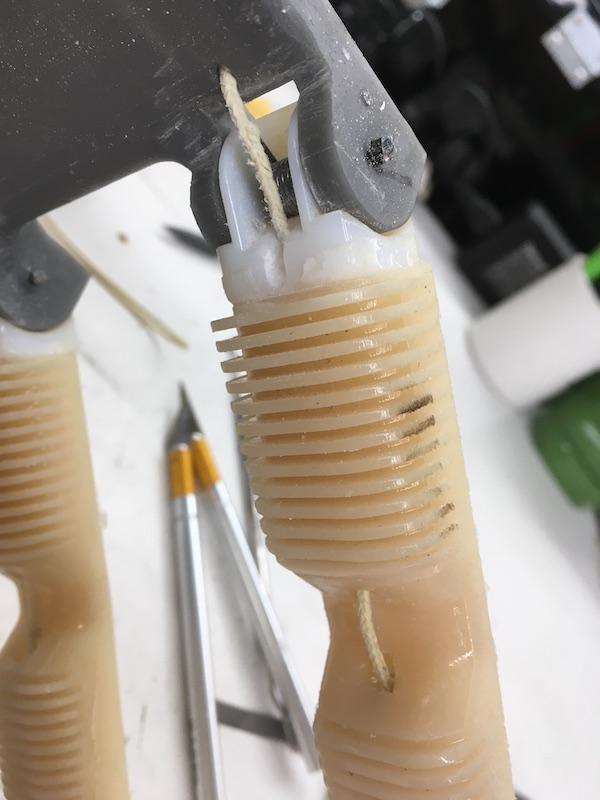

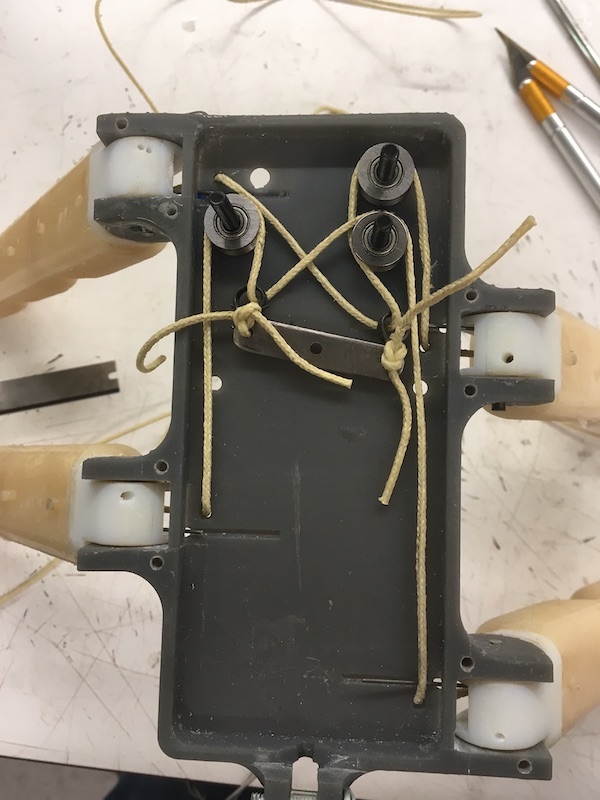

20 June: Spent a lot of time figuring out the best method to thread a kevlar line through the Ocean 1k fingers and after trying many methods on one finger the best solution was to just drill a bigger hole with the drill press. The process was much smoother after the first finger. After threading the new line through each finger Wison had me move on to making the system cleaner by cutting any excess rope and ensuring that all parts are assembled per the design specifications.

Threaded Finger and Assembled mechanism

18 June: Got set up in the lab with Wilson to work on the hand that will be used in the Ocean 1k project. Will be moving on to work on the TRI hand grippers later this week. More Specifically will be working on the hardware aspect of the TRI project helping to create and test the hand's ability to grasp objects.

11 June: Got started on the BDML wiki. Safety training = tomorrow.