On this page... (hide)

1. Documentation Observations and FAQ

1.1 Your target readership

Your target audience is not the ME112 teaching staff, it's somebody who generally knows the content of ME112 and knows in a vague way that you did something with ducks. She doesn't know what "the drag test" is or what the "the kiddie pool is." Fill her in about your project assuming she has NOT been following it closely.

1.2 How to organize the analysis narrative

You have various options how to frame your story. For example, you could start by asking "How much power does it take to drag a duck through water at a reasonable speed?" If you had a perfect propellor, this is all the power it would need. Then you might consider, "How much power does it take to achieve the desired paddling motions at speed?" This immediately tells you something about locomotion efficiency. In the worst case, you are just churning water and not going anywhere, in which case your locomotion efficiency is zero.

Finally you might ask, "How much power actually went into our motor?" But you don't need to do a detailed transmission analysis like you did for crawlers.

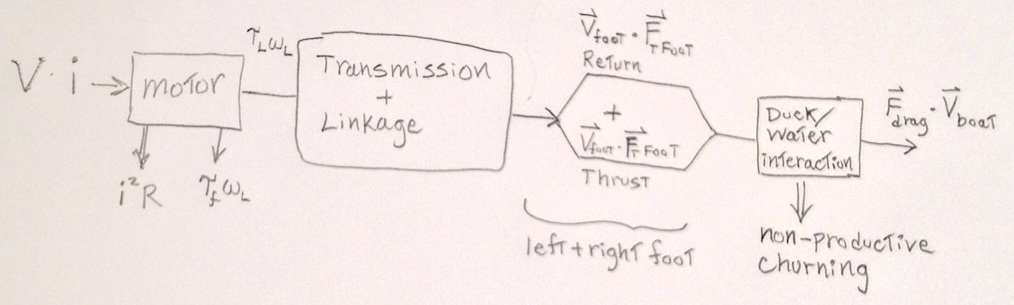

one way to think about where power goes in the duck

1.3 Don't forget... (Issues)

total speed

Don't forget duck speed added or subtracted from paddle speed (depending where you are in the cycle)

labels

When plotting your coupler curves, you can add stuff by hand -- like key points that you want to talk about. You can superimpose the paddle shape (by Powerpoint or Inkscape or Illustrator) if too tedious to do in Matlab. You can also draw things like COR by hand if you want. Most usefully: How about sketching in the approximate waterline? - This really helps to understand the coupler curve in context.

actual motor voltage in operation

Don't forget that a nominal 3 volt motor, if you give it 6 volts worth of batteries, will not be getting 6 volts. At no-load, it might come close. But if it's drawing more than 1/4 of an amp, the batteries will not be giving it close to 6 volts. If it's drawing, say, 1 amp, you might only be getting 3 or 4 volts across the motor! Only way to be sure is to measure the voltage across the motor terminals.

Remember, batteries have internal resistance, so the voltage they deliver drops with current demand. And the less fresh they are, the more noticeable this becomes.

Is it possible that you could increase your gear ratio and actually go faster? Yes. If your motor was previously "bogged down" and drawing too much current, then the voltage it was actually getting was probably much lower than the nominal battery voltage. But with a higher gear ratio, it needs less torque and consumes much less current. So it is likely getting a higher voltage and therefore spinning faster -- perhaps even sufficiently faster to compensate for the change in gear ratio?

Power inconsistency?

When I compute my coupler velocity and then get the estimated maximum paddle force, the corresponding required power is higher than my motor output. What gives? Answer: probably speed gives. Your motor can only produce so much power output. If the required paddle power is too high, the motor will slow down, which slows the paddle down. Recall, power in water goes as speed^3, so a modest reduction in speed at some point in the cycle will quickly drop the power down for that part of the cycle.

2. Duck Observations, March 12-14

It was good to see a bunch of ducks training in the Arrillaga West pool today. We had some general observations from the event:

2.1 Pool Rules

- The atheletics staff ask: Please no food (don't bring your lunch), no sodas, no glass. Only plastic water bottles!

- You can invite a friend and help them check in. Explain it's for the ME112 ducks event.

2.2 About the speed...

We will be scoring speed generously ;-) If your duck paddles along at a reasonable duck-like speed, that is more important than trying to squeeze an extra few centimeters per second at the expense of having things become unreliable or frantic looking.

2.3 About reliability

A number of ducks are in the "it works every third time we put it in the water" phase. Making things more precise and reliable will also probably make the motor effort lower, which will reduce stresses in the transmission and links, which will further improve reliability!

- Solder motor leads and provide strain relief so the wires don't break at the motor terminals. Hot melt glue can help. So can anchoring the wires somewhere just away from the motor so when you pull on the wires the stress does not go to the motor terminals.

- Tighten those joints. Cut or sand screw posts that are too long. Provide enough spacers. Glue one side of a screw post to the link it passes through, only one side needs to pivot freely. If screw posts or bolts are loosening, add a drop of superglue -- you can still unscrew them with tools, but they won't spontaneously unscrew.

- Consider an on-off switch so that you can have reliable battery and motor connections everywhere.

2.4 About wear and tear

Need for Speed: -- The other day, your motor was chugging along happily at a gear ratio of, say, 400:1. You want to go faster, so you pick a gear ratio of 126:1. But remember that force on the paddles goes as velocity squared and power goes as velocity cubed! So your motor needs to work much harder now. It is perhaps bogging down and drawing a lot of current (you can tell because the linkage motion is getting a bit erratic and it makes a funny noise). You compensate by increasing the voltage, which of course produces more current (more torque) and higher speeds. But force in water goes as velocity squared so the forces everywhere are now even higher. Sooner or later your mechanism starts to show signs of failure. Perhaps your motor pinion starts to wear out. Or a crank arm breaks where it is attached to the shaft. Or the motor itself burns out. Or gears start slipping....

All this is a sign that you should go back to the original higher gear ratio and, if you want more speed, focus on other things like more efficient (curved?) feet, or a sleeker hull for less drag, or...

Fatigue: -- You've been doing a lot of experimenting at various speeds, with different kinds of keels, etc. You also just added that auxiliary biomimetic motion. And suddenly, your crank arms are slipping. Your duck is going in and out of phase... This is a sign that the original solution of lasercut hexagonal holes in acrylic links on hex shafts was not a long-term solution. It lasts for a couple hours. What to do? You can:

- have spare links and be prepared to change them easily

- reinforce the acrylic with something stronger, like a brass collar and set screw, glued to the link

- for a quick & rough fix, you can drill a hole in a piece of aluminum that is about the size of the inscribed circle of the hex shaft. If you gently pound (with a hammer) the end of the shaft into the hole, it will cold-form the aluminum to a tight fit on the hex shaft. This solution is obviously not very removable... but it is pretty strong when it is glued to an acrylic link piece

2.5 About guidance

- Each team is allowed to have a designated aquanaut to help a bit with guidance, start and stopping. If your team doesn't have a designee, we have volunteers to help.

- Consider tapering the front of your design. Also, don't make it any wider than it needs to be: the wider it is, the more steering torque you get when a corner touches one of the lane guides. Also consider a low-friction material for the bumpers.

- Consider a piece of sheet metal for a rudder or keel that you can easily bend a bit by hand for adjustment, depending on whether it goes a bit to the left or right on the day of the event.