Category: SummerBlogs

This summer I am working on two projects:

- Tadpole robot

- IFOS space gripper

Week 8 (8/8 – 8/12)

V11 design

Tadpole

Redesigned the tadpole to be around 10% smaller (at the request of the biologists), and made the appropriate changes to preserve important dimensions and function. However, this made the assembly much more difficult to complete. Connecting the rubber band to the side of the lever has proven to be especially challenging.

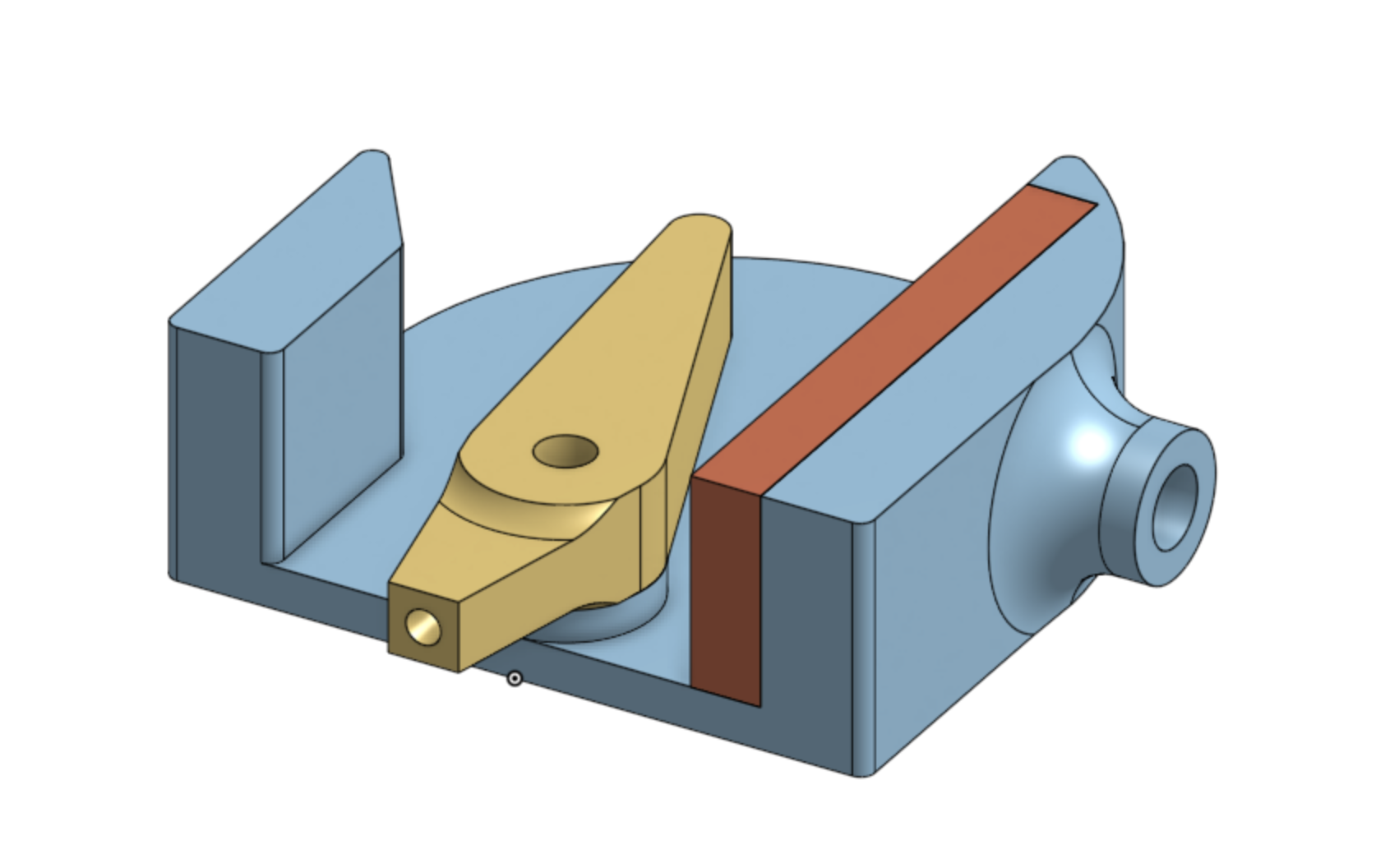

Space Gripper

This week I put the materials search on the back burner for a bit and did some other things. First, I began to make a list of parts needed to create two new prototypes. Next, I began work on a new gripper from scratch to (1) better understand the mechanisms, and (2) to make it changeable as needed, since I was having difficulty following and editing the original design.

Week 7 (8/1 – 8/5)

Tadpole

Spent this week building another prototype with the new metal tubing that came in from McMaster. We made a piece to connect the plastic and metal tubing together, but otherwise the assembly was the same as before. This time, however, we tested it in a cup of water with excellent results.

Space Gripper

The search continues...

Week 6 (7/25 – 7/29)

Tadpole

Silicone head and tail

At this point, the design phase seems to be wrapping up and we are working on putting together a fully functional Tadbot. In practice, this has proven to be more challenging than anticipated. We cast our first silicone parts on Tuesday 7/26 and Wednesday 7/27, which were not perfect by any means; making sure they cured properly and without an unacceptable amount of air bubbles took a few tries. Additionally, using superglue as an adhesive with such small parts has resulted in several cases of rendering parts unsalvageable, requiring a complete restart of the assembly. To make the final construction process easier, we made minor ad hoc revisions to the part models and assembly techniques.

Space Gripper

Met with IFOS in person for the first time on Friday. Got acquainted with the employees and got started on setting up software to read the data that comes in from the gripper's FBG sensors. Meanwhile, the search for materials continues as before.

The only working prototype

Week 5 (7/18 – 7/22)

Tadpole

Continued work on the V8 Tadbot design. The physical assembly proved to be the most difficult part due to the very small size of the parts. We spent basically the whole week just trying to get a semi-functional prototype together, mostly as a proof of concept. The black plastic piece acts as a spring to push the lever counterclockwise from the bottom while the blue string pulls the lever clockwise from the top.

Space Gripper

The search continues...

Week 4 (7/11 – 7/15)

Tadpole

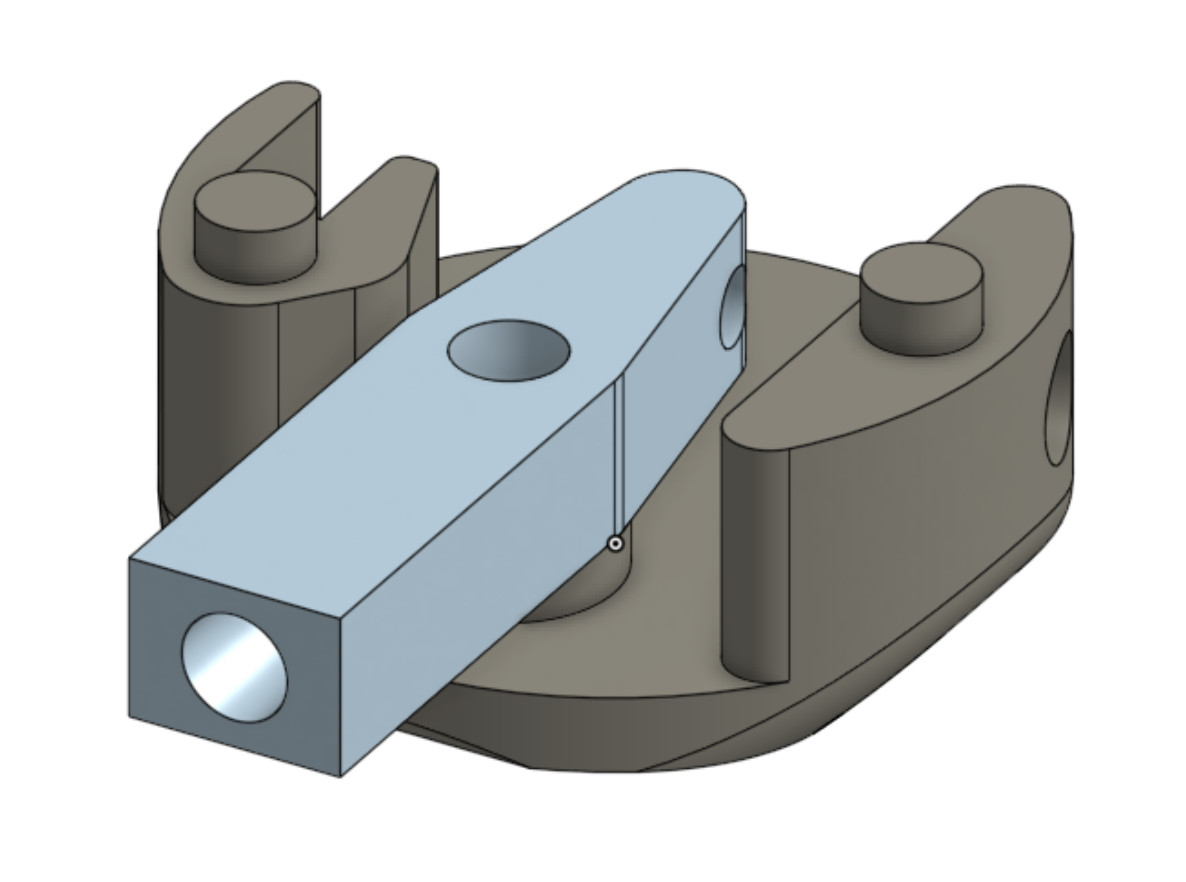

We made a major change to the actuator design. We did away with the slider piece entirely because the plastic-on-plastic action had too much friction. Instead, we will now have the pin itself slide along the rail. Additionally, we added a support underneath the rail that connects to the motor holder to prevent the part from breaking during assembly, which it did the first time. Additionally, we made a semi-functional prototype of the V7 design

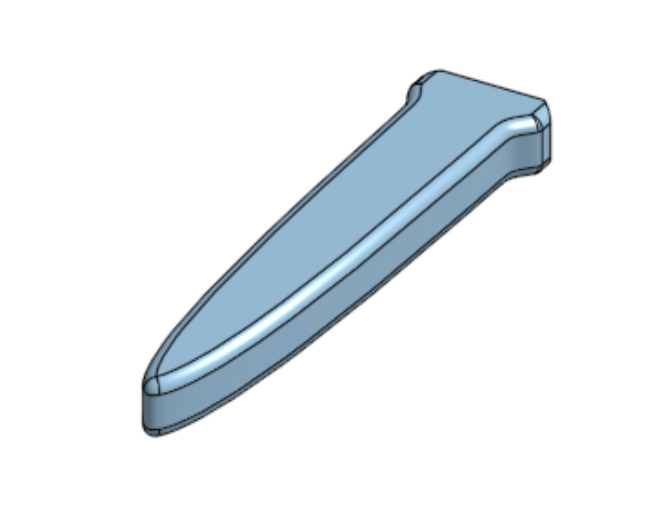

While I was away, my lab partner started work on the V8 Tadbot design, which now has CAD models for casting the tail and outer membrane. The body is smaller than before, since the dimensions of the previous designs did not account for the fact that the entire mechanism needs to be enclosed in silicone.

Cast

Body

Tail

Space Gripper

Continued the search for space-safe materials for the gripper. This has proven to be extremely tedious and slow.

Week 3 (7/4 – 7/8)

Lab took the day off on Monday 7/4

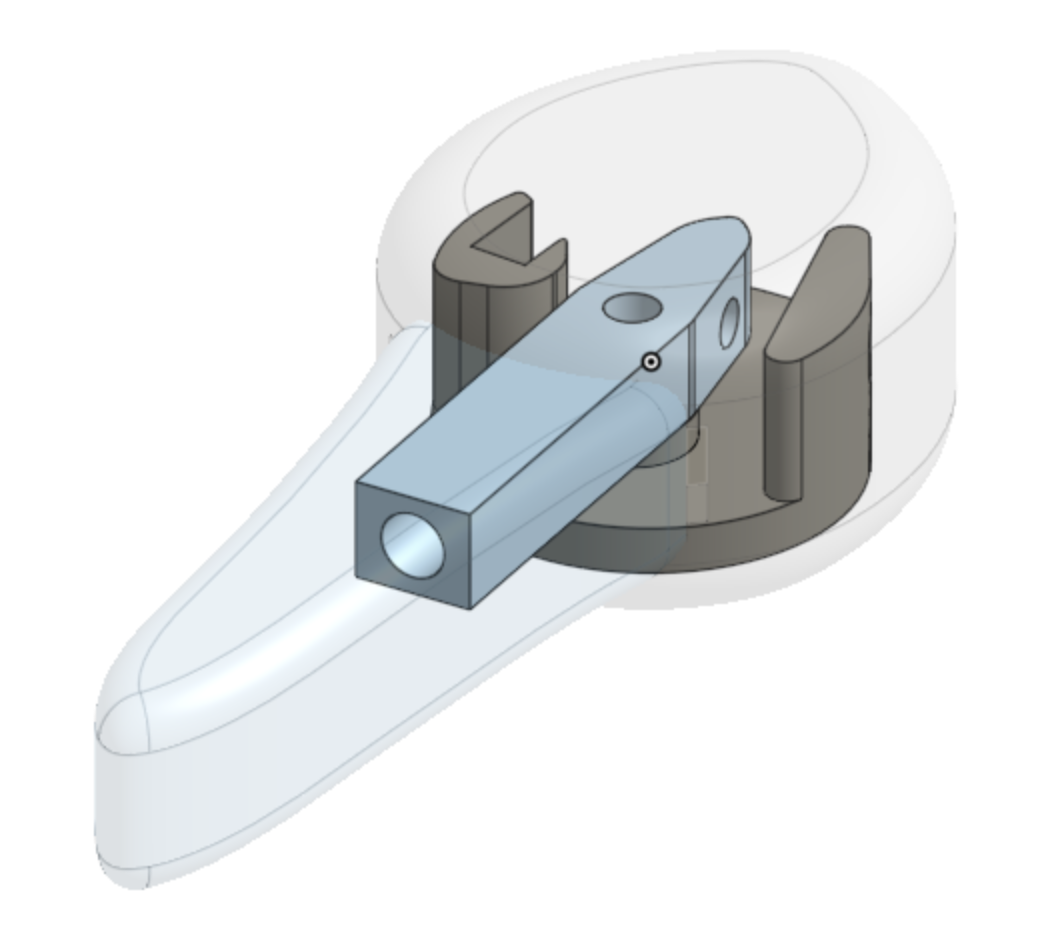

V7 design

Tadpole

Worked on the V7 designs for Tadbot (that's its name now). The biggest change from the previous designs is that we did away with the membrane idea entirely. Instead, we are using a motorized external crank-slider mechanism attached to a cable/string to move the lever. The actuation was designed separate from the body of Tadbot. Additionally, we added a cover that will be glued to the top of Tadbot.

Space Gripper

Most of the contacts we reached out to did not respond, so I began the search for space-safe materials to be used for constructing the gripper. The harsh environment of outer space means that vacuum conditions, solar radiation, and extreme temperatures all need to be taken into consideration. Intense vibration during the rocket launch is another cause for concern. Many plastics and elastomers that work well in terrestrial conditions break down in space, meaning suitable materials in these categories will be especially difficult to find.

Week 2 (6/27 – 7/1)

Thursday 6/30 was lab clean up day, which took all day

Tadpole

V5 design

Created some OnShape models for the tadpole robot prototypes. The V4 design was created by me and Guadalupe Bernal on Monday 6/27. V5, developed on Tuesday 6/28 by both of us, is a revision of the V4 design. The most notable change are:

- The base changed from entirely circular to the front half being circular and the bottom half being square. This increased the width of the base and allowed for more freedom to change the wall and pipe locations without changing their relative angle to the lever.

- Due to the extra space, it became possible to increase the length of the lever without reducing its range of motion.

Space Gripper

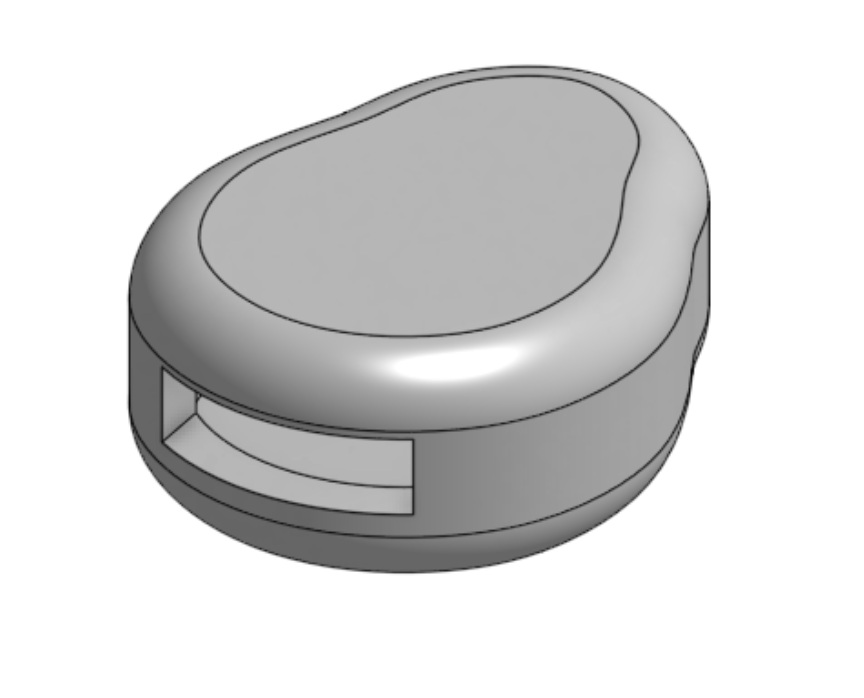

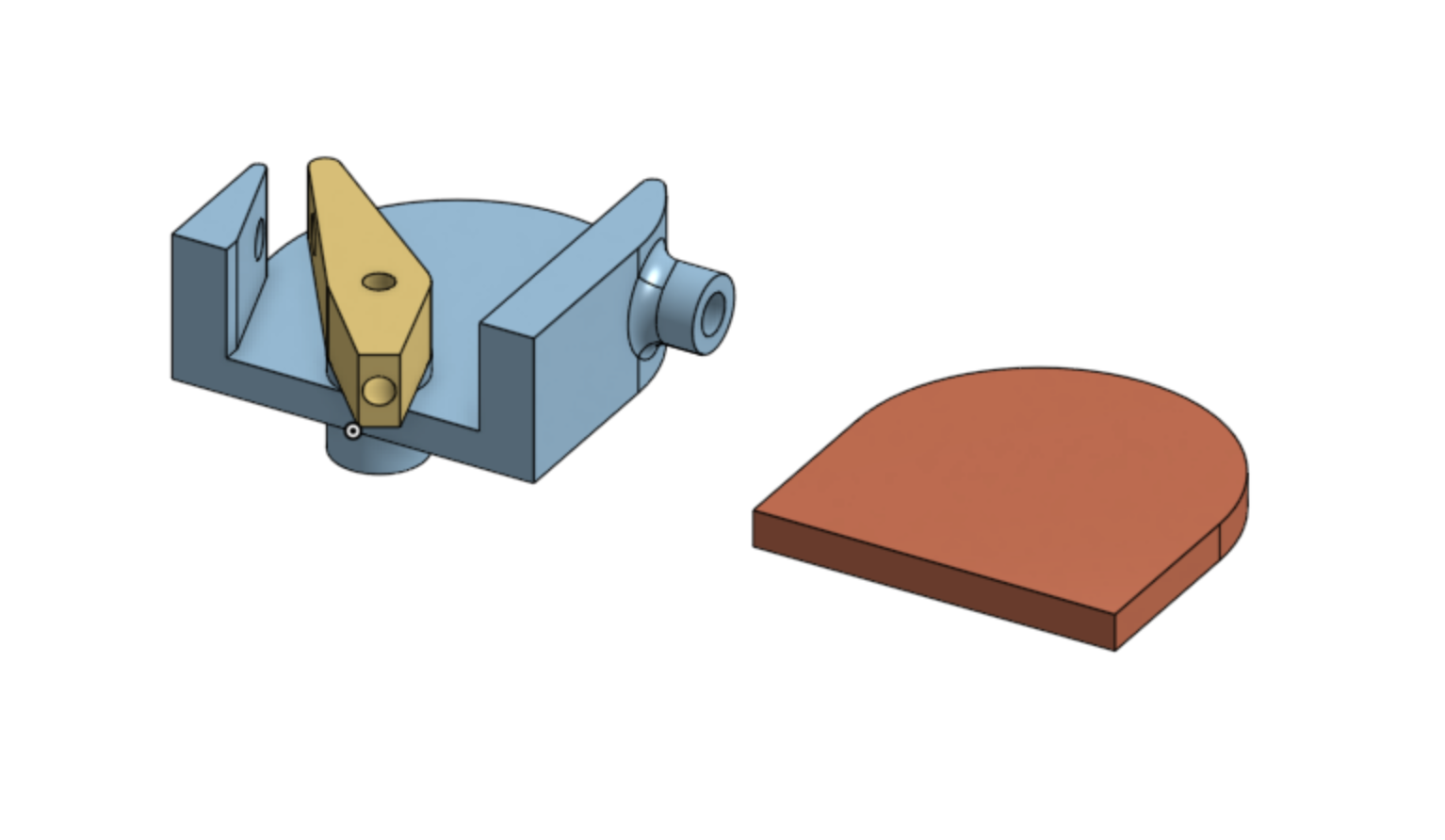

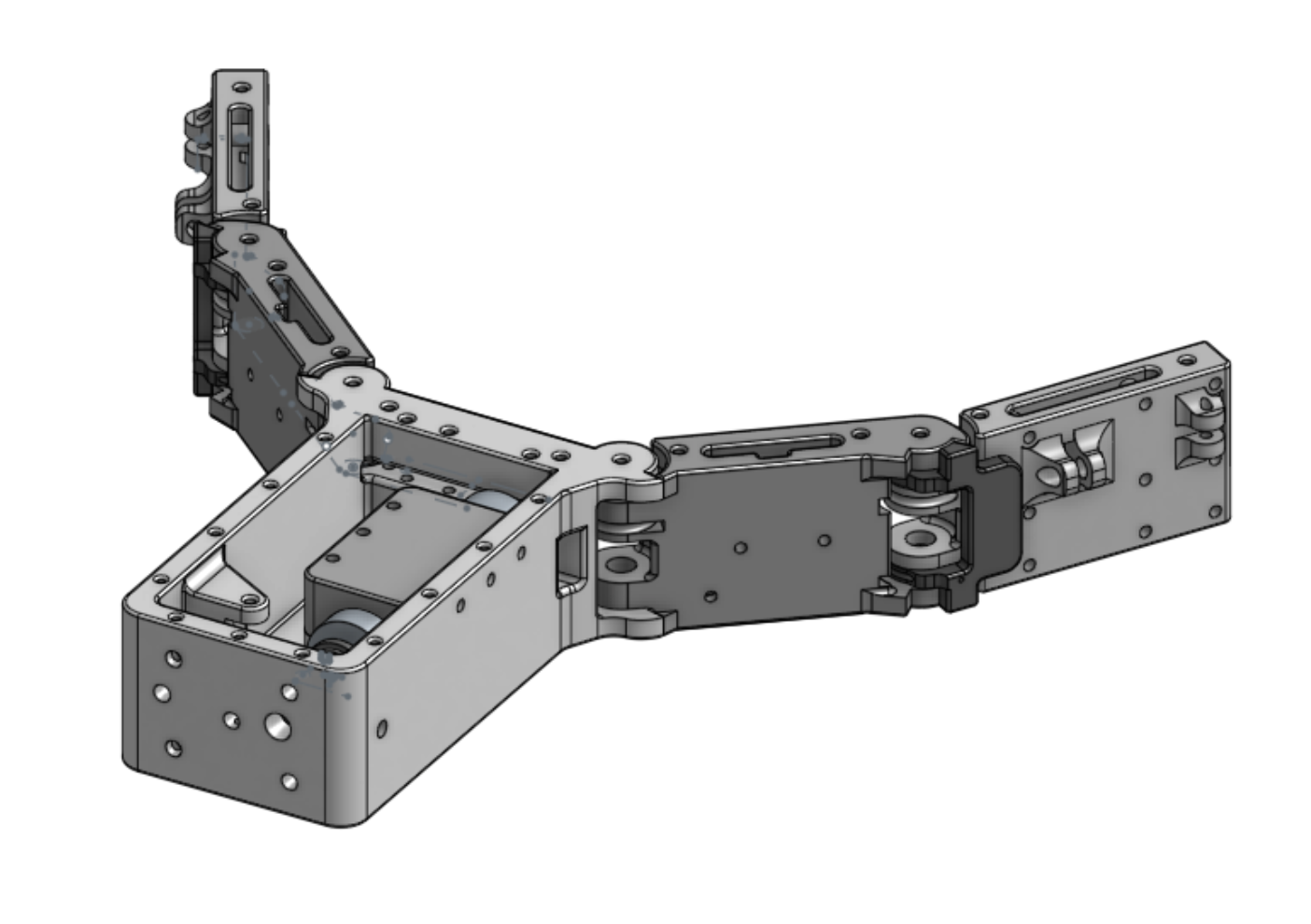

Sam's model

Started work on the FBG gripper – space qualified prototype with Xinyi Liang. A first task is to look up contacts and sources of information for space-qualified materials that are readily available.

- CubeSat groups

- NASA contacts

Before I started to work on this project, Sam Frishman made a detailed gripper model which was very helpful in getting me up to speed on what the finished product should look like.

Week 1 (6/20 – 6/24)

First week of the program. Unfortunately, campus experienced a power outage on Tuesday 6/21 that lasted through Thursday 6/23, which slowed the initiation process considerably. Despite this setback, I completed the following tasks:

- Set up my pages and was introduced to OnShape.

- Training for laser cutter and silicone/urethane casting

- Retreat with the lab group on Wednesday 6/22

I used the downtime to improve my OnShape skills.