categories: Adhesion

How do BDML's gecko-inspired dry adhesives work?

This Veritasium video is a great overview of how gecko adhesives work! We highly recommend watching this before getting started: The Stickiest *Non-Sticky* Substance

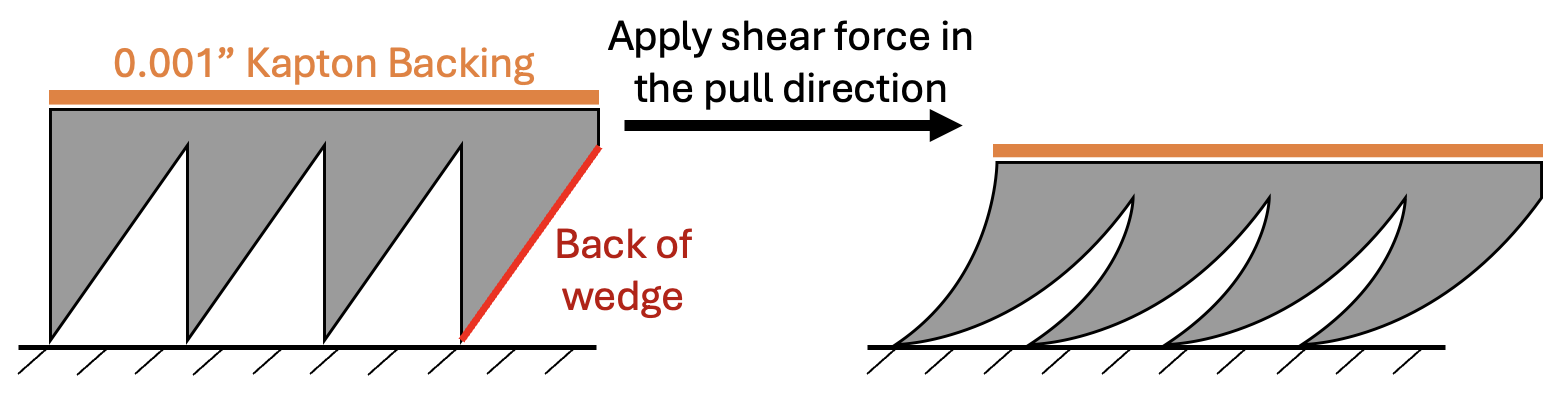

BDML's gecko-inspired adhesives us a wedge microstructure to take advantage of van der Waals forces and adhere to smooth surfaces. To adhere, wedges are placed onto a target surface. A shear force is then applied in the pull direction, such that the wedges "lay down" and conform to the target surface (see gif below).

van der Waals forces are directly proportional to the actual contact area of the adhesive onto the target surface.

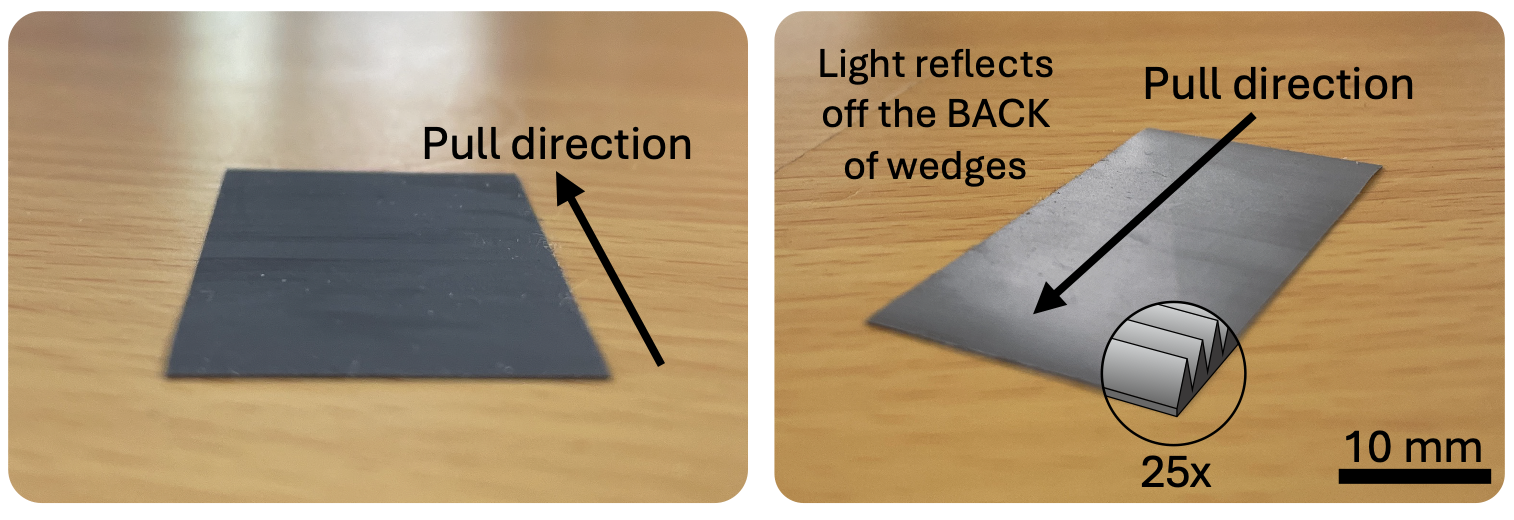

Determining pull direction

Light reflects off the back of the adhesive wedges. Determine the pull direction by observing the adhesive from a shallow angle and rotating until a “shiny” side appears. The pull direction is towards the back of the wedges (see image below).

Cleaning the adhesives

Dust will build up on the adhesive over time, resulting in poor adhesion. To clean a sample, simply dab the adhesive with something tacky – tape and lint rollers work well.

Common Pitfalls

- Peeling

- For flexible-backed adhesives: Applying too much normal force when engaging the wedges can result in peeling. Make sure you are applying a force no more than 7° from pure shear force to the adhesive sample.

- For rigid-backed adhesives: Attempting to adhere too large of a sample can result in peeling, as a small area of poor contact will propogate to the entire sample. Try using a smaller sample! If using the adhesive for heavier lifting, load sharing may need to be employed. See Human climbing with efficiently scaled gecko-inspired dry adhesives and From grasping to manipulation with gecko-inspired adhesives on a multifinger gripper for some interesting examples of this!

- Poor surface contact

- Poor surface contact occurs when using too rough of a target surface. Gecko adhseives perform best when used on surfaces with a roughness Ra value below 1 μm, with a sampling length of approximately 800 μm. See this paper for more info.

- For rigid-backed adhesives: Poor lamintaion of the flexible kapton-backed adhesive (bubbles etc) onto stiff backings can result in poor contact. First, make sure your backings are perfectly flat, sanded up to at least 800 grit sandpaper. Use thin double-sided tape (I like this Uline double sided tape), or a thin layer of super glue rolled onto the backing surface using a rolling pin to ensure flatness.

Applications

Gecko-inspired adhesives have been used in a variety of applications. More info on some of our personal favorites can be found below:

Gecko-inspired adhesives are also currently used in industry! Check out Flexiv's Grav Enhanced Gripper.