IEEE ICRA 2012 Needle Steering Workshop

Submitted IEEE ICRA 2012 Needle Steering Workshop Astract Web Link, which will be held on May 18, 2012

Passive needle steering

- Previous passive needles

- Conventional diamond tip needle: 3D Translation at the needle base enables the needle tip changed its positon and orientation

- Highly flexible asymmetric tip needle: Axial rotation & insertion change its bevel orieantions, resulting in the interation force at the tip that is the driving force for the steering.

- Pre-cuved tube needle: This type of needle consists of varoius pre-curved tubes, each of which has diffrent constant cuvatures.

- Tendon-driven needle: PneumRx marketed a tendon-driven needle, named Seeker, a few years ago, which has a joystick at the base that is directly connected to the tip through a strand of metal wires. Manipulating the joystick, the entire needle could be bent, eventually its tip orientation and position can be changed. This needle's target organ looks like a softer tissue such as lung and liver rather than a denser tissue of prostate.

PneumRx Seeker steerable needle

Active needle steering

Active needles has a few active joints, which enable operators to control the specific parts by transmiting energy externally for steering the needle to reach a target.

- Previous research on the design of actively steerable needle

- Magnetically steerable needle tip: A needle with a thinner hinge near tip has been studied, whose tip can be bent by the exteral magnetic force. Apparently, the design concept of thinner hinge is more susceptable to buckling.

- Piezoelectric material deposited smart needle: This is the first design concept of an active needle, which has depositted piezoelectric materials along the whole needle. However, their simulation shows tip defelction is insufficient to get a significant tip orientation change.

- Proposed novel active needle

We proposed an active needle with a flexible joint near tip, which allows operatore control tip orientation that determines needle inserting direction within human tissue. The active joint of the needle consists of the following components

- superelastic nitinol tube with a set of slits

- a multilumen PTFE tube that plays important rols such as, aligning multiple fibers with the SMA wire, supporting SMA wire within the tube, and facilitating integration process. This material is biocompatible and transparent to IR.

- two optical fibers for activation that will have a sidetap, so total four spots of heating is available.

- one plastic fiber with a sensitive region to banding as a curvature sensor

- one fiber with FBGs to as a temperature sensor

Optical actuation methods

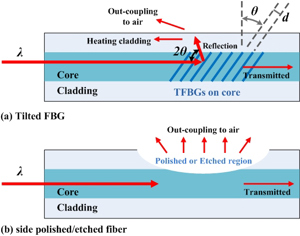

Principle of TFBG and side polished/etched fiber

Previous experiments of optical actuation of an SMA wire resulted in that distributed heating shows better contraction performance given similar amount of power. Considering this fact and the limited number of fiber in such a slender needle, we proposed to use side optical heating of the SMA wire. Each fiber will have one side heating spot, thus the needle will have total four heating spots to activate a 18 mm long SMA wire.

- Side optical heating method.

- Tilted FBG (TFBG): a wavelength specific reflector for out-coupling laser to the air can be written on a fiber, but its main drawback is low out-coupling percentage and a little of which is coupled to cladding.

- Side polishing/Etching: a portion of cladding can be removed to take out laser by a few different methods such as polishing, direct writing by laser, or chemical etching with a dangerous HF acid. Instead, a much safer glass etching cream can be used, but the etched depth with the cream need to be investigated.

- Thermal cenmented fiber tip: Although this can increas thermal mass of the system, the high conductivity of the cement can be applied at the heating spot for more distributed heating

Prototypes of active needles

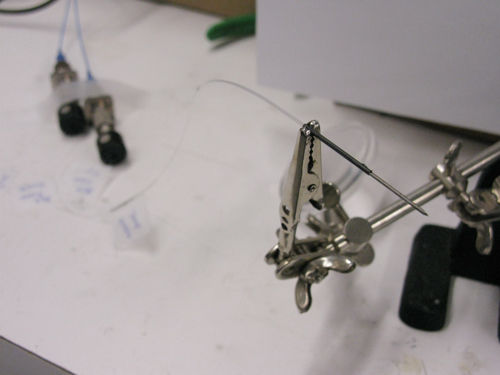

1st functional prototype

- 1st working prototype

- We built the 1st functional prototype to present the feasibility of optical activation idea.

- This prototype has the active part of the needle, the critical part, with its tip. It has two optical fiber for heating, each of which has thermal cemented fiber tip to delver heat to the SMA wire through conduction and to diffuse the directional laser. Two dummy optical fiber simulationg curvature & temperature sensor are also embedde together.

- The thermal cement has carbon powder (about 3 cement powder: 1 carbon powder ratio is the best for the chamical reaction between the mixed power and solution) to increase the laser absorption, and it was measured about 35% by a power meter.

- It turns out that lots of laser is coming out from the slits on the tube, which causes less efficiency and slow response. Gold coating might be the solution for this issue.

- Also we learned that the mechanical anchor through two holes should be improved, because one part near base does not have a solid rod pressing the SMA wire from the inside of the NiTi tube.

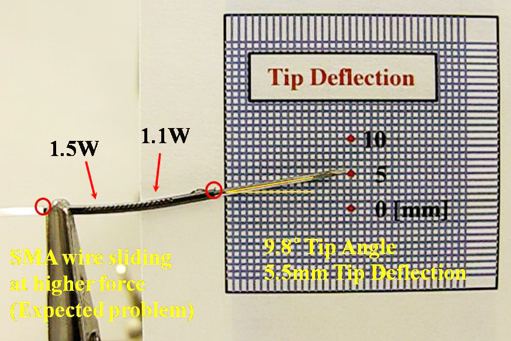

Tip angle of 9.8 Deg achieved with 2.6W

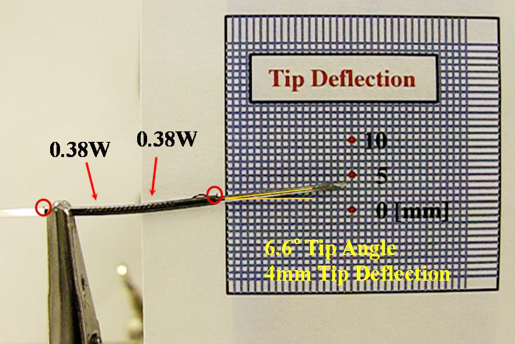

Tip angle of 6.6 Deg achieved with 0.76W

Page last modified on March 16, 2012, at 03:25 PM