new web: http://bdml.stanford.edu/pmwiki

TWiki > Main Web>TWikiUsers > MattEstrada>MattSummerResearch (06 Jul 2011, MattEstrada)

Main Web>TWikiUsers > MattEstrada>MattSummerResearch (06 Jul 2011, MattEstrada)

-- MattEstrada - 21 Jun 2011

Currently moving this over to PM Wiki!

http://bdml.stanford.edu/pmwiki/Main/MattEstradaJune 20

- Introduction to the lab took all day. Listened to a lot of people talk about their research, all of which seemed pretty cool.

- Introduction to my past projects:

- Learned to fabricate gecko adhesive (Directional Polymeric Stalks variety) using a mold Sangbae had brought over with him

- Worked on process of fabricating a composite leg (foam core with 2mm plastic shell). Learned more about casting materials and creating toolpaths/running the CNC mill.

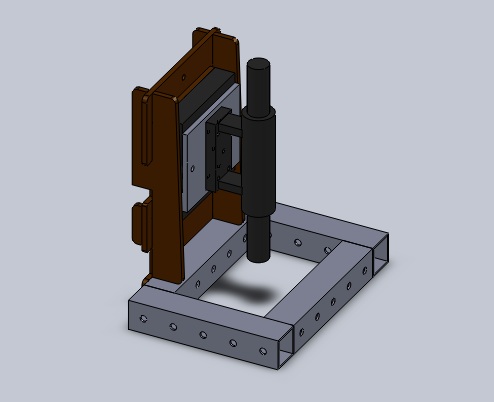

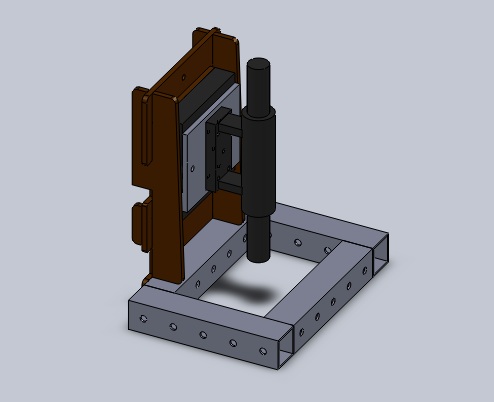

- Designed and built a test gantry to simulate running for a single leg. More practical building/ordering from Mc Master/designing for minimal assembly.

- Vague goals for this summer

- Learn tons of useful skills for robotics

- Come out with some solid progress in at least one project that helps out the lab

- Get a tan after spending the past 3 years in New England

- Thoughts on cool projects I'd like to work on

- Gecko Adhesive seems super relevant to my past experience and a good way to dive into something quick.

- I think it would be cool to pick up something in addition so that I can have a distraction from banging my head against the desk when gecko adhesives aren't coming out right

- It would be useful to build my background in practical electronics, an area which I am inexperienced in

- Mechanical design and building is always a fun job

June 21

- Noe gave me the details on the state of the indenting process

- Useful to think of adhesion in a 2D state-space (Normal Pressure vs. Shear Pressure). Failure points at different configurations encircle an area of safe operation for adhesion.

- Process of indenting is done on the mill. The z-axis is zeroed by shining a light behind the stock and the tool is lowered until it blocks out all the light. The mill advances at an angle matching the razor to indent into the wax.

- The Levil mill cannot make things flat enough for our purposes. It has a >10 micron error over the workspace. The HAAS will hopefully be better.

- Used Image Pro Plus on the microscope to measure stalk height, interior angle, and backing thickness * A discrepancy showed up between the stalk characteristics aimed for and what was actually measured. The stalks indented at 30 deg and 40 deg were both ~20 microns shorter than desired. The ridges also had a larger interior angle of 30 degrees rather than 20 degrees.

- Went with Eric to the machine shop while he measured some tool dimensions and tested commands. Maybe he will let me touch the mill by the end of the summer.

- Barrett gave a tutorial on how to use the Adept robotic arm and sent some tutorials.

June 22

- Signed up for a Mendeley account. Still a little unsure how to use it, but I'll ask around.

- Sat with Eric in the PRL while he did more prep on the HAAS, but I did some lit review and picking his brain about indenting this time.

- Played with the Adept arm, but only turned it on an controlled it manually.

- Read some of the manual on files and directories. It's a little unintuitive but doesn't seem too hard. Next on my list is to write a program.

- Spoke to Barrett about the desired key task for the Adept.

- Open loop control, seems like I just have to move the hand forward and rotate, unless I misunderstood.

- Doesn't seem to be much compliance in the system (Rigid robot arm/metal hand/rigid key/rigid lock), so if I'm off by a little bit, it's probably going to fail. Hopefully the key would just slip out of the hand instead of breaking something.

- Need to hack together a mount for the lock (and also buy the lock)

- Not sure how hard it is going to be to align the center of the key will the axis of rotation on the robot arm

- Noe went over how to use the inking platforms. The home-made micro-controller was cool. I took notes on the somewhat cryptic display, which only has a few, basic functions so it's not that bad.

- Still need to mount the camera at the correct height for the inking process.

- Need to figure out how we are going to mount the wafer to the underside of the glass in the new inking platform.

- Noe took Thea and I over to the LFL to show us the casting process, quartz wafers, microtome mount (but not version 2.0), and wax block. I think I've seen all the tools and materials used in the process now other than the Matlab script/Gcode toolpaths.

- I'm excited to get started indenting and inking, but I expect the pain to set in shortly thereafter. Blood, sweat and tears usually go into making things that are super tiny.

- Read some articles on adhesion, but still have more to go.

- Microindenting for the Manufacture of directional dry adhesive (2011)

- Paper submitted by the lab in May (?). Helped me understand the process a little more.

- Surface energy and the contact of elastic solids (1971)

- Pretty theoretical & mathy. Talked about surface forces and energies. I didn't understand most of it too well so I may go back and read it again if I think it will help understand adhesion.

- Thin-film peeling: the elastic term (1975)

- Short & concise theory on peeling

- Microindenting for the Manufacture of directional dry adhesive (2011)

June 22

- Lab Retreat

- First goal for this summer is getting somebody to climb a glass wall !!

- Mark mentioned creating a wall with slots for pegs to practice two-point climbing. It would also probably be helpful to rig up a belay system and do some research on rock climbing, but I'm not sure when I'll find time for that.

- Would also like to pick up some mechatronics skills

- Personal goal: Make friends.

- First goal for this summer is getting somebody to climb a glass wall !!

June 23

- Read some more papers

- Effects of contact shape on the scaling of biological attachments (2005)

- Adhesion and friction in gecko toe attachment and detachment (2006)

- A microfabricated wedge-shaped adhesive array displaying gecko-like dynamic adhesion, directionarlity and long lifetime (2009)

- Adhesion meeting

- Notes to self- software for creating toolpaths is on John's computer & on the laptop

- Make sure not to go past the machine's workspace, which is about 2" from the edge of the mounting block

- The directions for measuring tool dimensions is not correct on the twiki

- BDML Meeting - brainstormed ideas for perching then crawling around on the side of a wall

- Regrouped with adhesion team and discussed immediate plans for improving inking process

- Going to try to mount the camera for a birds-eye view of the inking process due to spatial constraints on the rig

- It would be ideal to do inking solely on pressure-guided feedback in the future

- Bringing in a heat lamp to speed up curing process. Heat the sample to 75-95 C and it should take ~30 min, which beats 36 hr.

- Going to try to mount the camera for a birds-eye view of the inking process due to spatial constraints on the rig

- Homework: design & build a mount to hold the camera

- Mount is going to be made out of masonite and cut out on the lasercutter. An adapter between the vertical slide and camera also needs to made out of aluminum. I'll ask someone to come with me to fabricate these on Monday to make sure I don't blow anything up the first time I use the particular machines we have here.

- Quick research on peg boards- used to build upper body strength for wrestlers, and potentially to practice climbing with gecko adhesion?

- Demonstrative video - http://www.youtube.com/watch?v=p1NwRfWeHIY

- Models that would probably be useful to us range from $185-$350 on this website. Each is 6' tall... not sure if they come with pegs

- Super basic instructions on how to make a climbing peg board

- http://www.ehow.com/how_6780712_make-climbing-peg-board.html

- Usually made out of 2" thick hardwood finished with 3 coats of clear varnish (optional). Perhaps two parallel 2x4's would do the trick? It would be cheaper.

June 23

- Spent the morning with Elliot in the LFL as he walked me through the specifics of the laser cutter. We did some quick math to compensate for the laser width and the pieces that fit together came out to a nice press fit.

- Went to the Thermo Sciences building with Noe as he walked me through the specifics of their Bridgeport mill to make an adapter to attach the camera's base to the one axis slide.

- Walked over to the Physics shop and Noe showed me how to buy bolts and other supplies.

June 24

- Bolted the camera to the three axis-slide

Ideas, requests, problems regarding TWiki? Send feedback